3540-BIT - Machine tap with straight flutes and spiral point

Code: 04453725210000B

Variant: M 10x1,5 6H

In stock

(>10 pcs)

| 04453725210000B

EAN: 8595111991184

€17,45

€14,42

excl. VAT

Variant: M 12x1,75 6H

In stock

(>10 pcs)

| 04453725212000B

EAN: 8595111991191

€21,10

€17,44

excl. VAT

Variant: M 16x2 6H

In stock

(>10 pcs)

| 04453725216000B

EAN: 8595111991207

€29,95

€24,75

excl. VAT

Product detailed description

Catalogue number: 3540-BIT

Machine taps with straight flutes and spiral point, metric and metric fine, DIN 376, DIN 374, steam oxided, suitable for structural steels, plain cast steels, free cutting steels, zinc alloys, aluminium alloys Si<10%, possible use in aluminium alloys Si>10%.

Features:

Thread M: ISO Metric coarse thread

Thread M: ISO Metric coarse thread Thread MF: ISO Metric fine thread

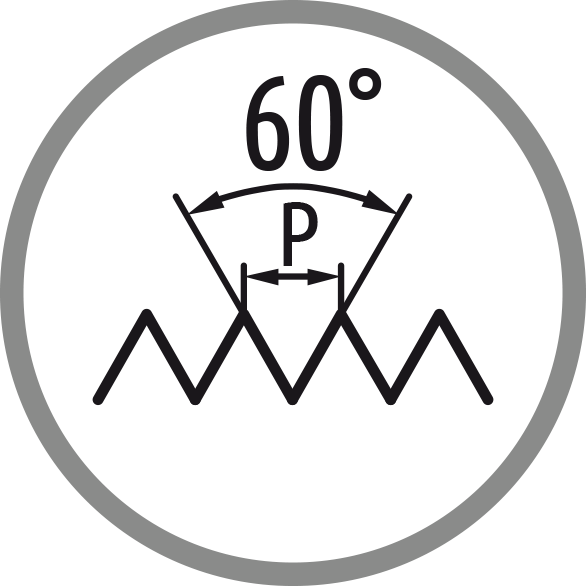

Thread MF: ISO Metric fine thread Profile sketch: 60°

Profile sketch: 60° Thread standard: DIN 13

Thread standard: DIN 13 Type N: Tap for steels up to 800 N/mm2

Type N: Tap for steels up to 800 N/mm2 Tap material: Super high speed steel

Tap material: Super high speed steel Coating: Oxidation

Coating: Oxidation Tap standard: DIN 376

Tap standard: DIN 376 Tap standard: DIN 374

Tap standard: DIN 374 Thread tolerance: ISO 2 - 6H

Thread tolerance: ISO 2 - 6H Chamfer B: Length 3,5-6 pitch

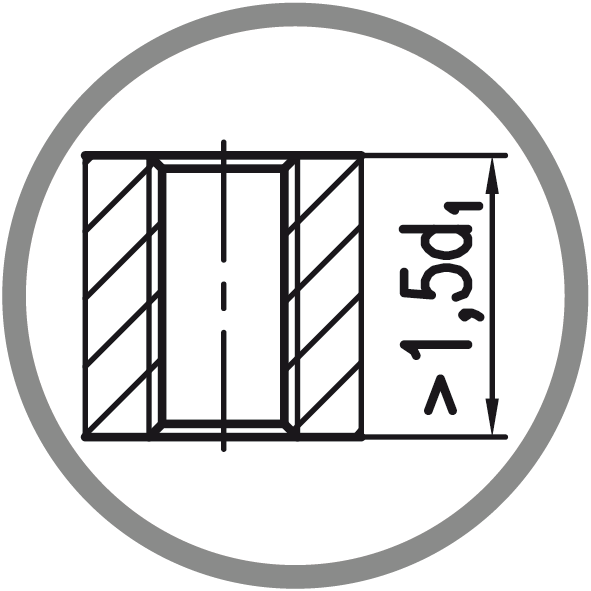

Chamfer B: Length 3,5-6 pitch Hole type: Through hole (thread length L > 1,5xd1)

Hole type: Through hole (thread length L > 1,5xd1)

Machined materials:

| Group | Machined material | Cutting speed |

|---|---|---|

| P1.2 | Plain cast steels <500N/mm2 | 6-10 |

| P2.2 | Structural steels <800N/mm2 | 10-12 |

| P2.3 | Plain cast steels <800N/mm2 | 12-15 |

| N8.1 | Aluminium alloysSi<10% | 14-20 |

| N8.2 | Aluminium alloysSi<10% | 12-15 |

| N11.1 | Zinc and zinc alloys | 10-12 |

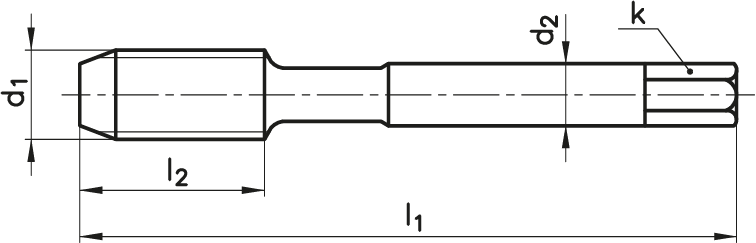

Dimensions:

| d1 | P | tol | l1 | l2 | d2 | a | hole |

|---|---|---|---|---|---|---|---|

| M 3 | 0,5 | 6H | 56 | 9 | 2,2 | - | 2,5 |

| M 4 | 0,5 | 6H | 63 | 12 | 2,8 | 2,1 | 3,5 |

| M 4 | 0,7 | 6H | 63 | 12 | 2,8 | 2,1 | 3,3 |

| M 5 | 0,8 | 6H | 70 | 13 | 3,5 | 2,7 | 4,2 |

| M 5 | 0,5 | 6H | 70 | 13 | 3,5 | 2,7 | 4,5 |

| M 6 | 0,75 | 6H | 80 | 15 | 4,5 | 3,4 | 5,2 |

| M 6 | 1 | 6H | 80 | 15 | 4,5 | 3,4 | 5 |

| M 6 | 0,5 | 6H | 80 | 15 | 4,5 | 3,4 | 5,5 |

| M 7 | 0,75 | 6H | 80 | 15 | 5,5 | 4,3 | 6,2 |

| M 7 | 1 | 6H | 80 | 15 | 5,5 | 4,3 | 6 |

| M 8 | 0,75 | 6H | 80 | 15 | 6 | 4,9 | 7,2 |

| M 8 | 1,25 | 6H | 90 | 18 | 6 | 4,9 | 6,8 |

| M 8 | 1 | 6H | 90 | 18 | 6 | 4,9 | 7 |

| M 10 | 0,75 | 6H | 90 | 20 | 7 | 5,5 | 9,2 |

| M 10 | 1,25 | 6H | 100 | 20 | 7 | 5,5 | 8,8 |

| M 10 | 1,5 | 6H | 100 | 20 | 7 | 5,5 | 8,5 |

| M 10 | 1 | 6H | 90 | 20 | 7 | 5,5 | 9 |

| M 12 | 1 | 6H | 100 | 21 | 9 | 7 | 11 |

| M 12 | 1,5 | 6H | 100 | 21 | 9 | 7 | 10,5 |

| M 12 | 1,75 | 6H | 110 | 23 | 9 | 7 | 10,2 |

| M 12 | 1,25 | 6H | 100 | 21 | 9 | 7 | 10,8 |

| M 12 | 1,75 | 6G | 110 | 23 | 9 | 7 | 10,2 |

| M 14 | 1 | 6H | 100 | 21 | 11 | 9 | 13 |

| M 14 | 2 | 6H | 110 | 25 | 11 | 9 | 12 |

| M 14 | 2 | 6G | 110 | 25 | 11 | 9 | 12 |

| M 14 | 1,5 | 6H | 100 | 21 | 11 | 9 | 12,5 |

| M 14 | 1,25 | 6H | 100 | 21 | 11 | 9 | 12,8 |

| M 15 | 1,5 | 6H | 100 | 21 | 12 | 9 | 13,5 |

| M 15 | 1 | 6H | 100 | 21 | 12 | 9 | 14 |

| M 16 | 1 | 6H | 100 | 21 | 12 | 9 | 15 |

| M 16 | 2 | 6H | 110 | 25 | 12 | 9 | 14 |

| M 16 | 2 | 6G | 110 | 25 | 12 | 9 | 14 |

| M 16 | 1,5 | 6H | 100 | 21 | 12 | 9 | 14,5 |

| M 18 | 1 | 6H | 110 | 24 | 14 | 11 | 17 |

| M 18 | 2 | 6H | 125 | 24 | 14 | 11 | 16 |

| M 18 | 2,5 | 6H | 125 | 30 | 14 | 11 | 15,5 |

| M 18 | 1,5 | 6H | 110 | 24 | 14 | 11 | 16,5 |

| M 20 | 1 | 6H | 125 | 24 | 16 | 12 | 19 |

| M 20 | 2 | 6H | 140 | 24 | 16 | 12 | 18 |

| M 20 | 1,5 | 6H | 125 | 24 | 16 | 12 | 18,5 |

| M 20 | 2,5 | 6H | 140 | 30 | 16 | 12 | 17,5 |

| M 22 | 1 | 6H | 125 | 24 | 18 | 14,5 | 21 |

| M 22 | 2,5 | 6H | 140 | 30 | 18 | 14,5 | 19,5 |

| M 22 | 2 | 6H | 140 | 24 | 18 | 14,5 | 20 |

| M 22 | 1,5 | 6H | 125 | 24 | 18 | 14,5 | 20,5 |

| M 24 | 1 | 6H | 140 | 26 | 18 | 14,5 | 23 |

| M 24 | 2 | 6H | 140 | 26 | 18 | 14,5 | 22 |

| M 24 | 3 | 6H | 160 | 36 | 18 | 14,5 | 21 |

| M 24 | 1,5 | 6H | 140 | 26 | 18 | 14,5 | 22,5 |

| M 25 | 1,5 | 6H | 140 | 26 | 18 | 14,5 | 23,5 |

| M 26 | 1,5 | 6H | 140 | 26 | 18 | 14,5 | 24,5 |

| M 27 | 2 | 6H | 140 | 26 | 20 | 16 | 25 |

| M 27 | 1,5 | 6H | 140 | 26 | 20 | 16 | 25,5 |

| M 27 | 1 | 6H | 140 | 26 | 20 | 16 | 26 |

| M 27 | 3 | 6H | 160 | 36 | 20 | 16 | 24 |

| M 28 | 2 | 6H | 140 | 26 | 20 | 16 | 26 |

| M 28 | 1,5 | 6H | 140 | 26 | 20 | 16 | 26,5 |

| M 30 | 1,5 | 6H | 150 | 28 | 22 | 18 | 28,5 |

| M 30 | 3,5 | 6H | 180 | 40 | 22 | 18 | 26,5 |

| M 30 | 1 | 6H | 150 | 28 | 22 | 18 | 29 |

| M 30 | 2 | 6H | 150 | 28 | 22 | 18 | 28 |

| M 32 | 1,5 | 6H | 150 | 28 | 22 | 18 | 30,5 |

| M 33 | 1,5 | 6H | 160 | 30 | 25 | 20 | 31,5 |

| M 33 | 3,5 | 6H | 180 | 42 | 25 | 20 | 29,5 |

| M 33 | 2 | 6H | 160 | 30 | 25 | 20 | 31 |

| M 35 | 1,5 | 6H | 170 | 30 | 28 | 22 | 33,5 |

| M 36 | 2 | 6H | 170 | 30 | 28 | 22 | 34 |

| M 36 | 1,5 | 6H | 170 | 30 | 28 | 22 | 34,5 |

| M 36 | 4 | 6H | 200 | 50 | 28 | 22 | 32 |

| M 36 | 3 | 6H | 200 | 42 | 28 | 22 | 33 |

Additional parameters

| Category: | Machine taps |

|---|---|

| Coating: | OX |

| Hole type: | through hole (thread length L > 1,5xd1), through hole (thread length L < 1,5xd1) |

| Machined material: | Plain cast steels <500N/mm2, Structural steels <800N/mm2, Plain cast steels <800N/mm2, Aluminium alloysSi<10%, Zinc and zinc alloys |

| Product line: | NAREX Zdanice Product Line |

| Standard: | DIN 374, DIN 376 |

| Thread type: | Metric ISO Thread, Metric ISO Fine Thread |

| Tolerance: | 6H |